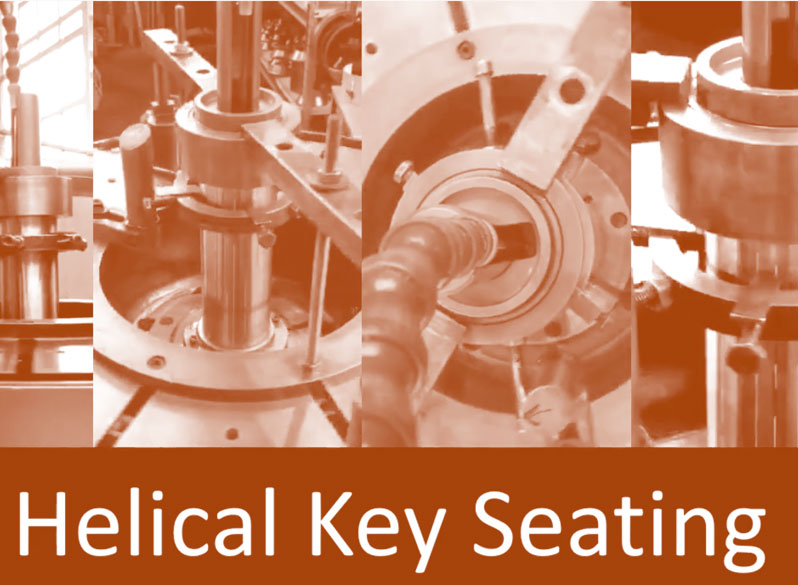

Helical Key Seating

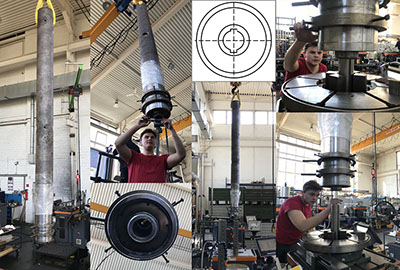

Electromechanically driven machines built by FRÖMAG set themselves apart with short primary processing, minimal non-productive times, a wide variety of applications, ease of use, energy conservation, environmental compatibility and of course high quality, reliability and cost effectiveness.

The Rapida series is especially wellsuited for:

- Machining keyways according to DIN

- Machining conical keyways, in conical or cylindrical bores

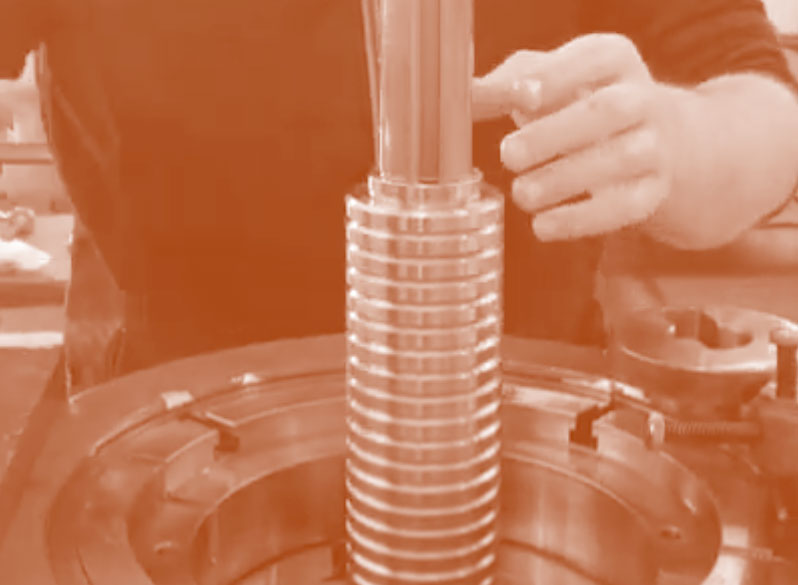

- Profile keyways, evolvents, serrations, square-cuts, spline profiles, tangential keyways, helical keyways

Start improving productivity and get in touch with us.

I

I